We design optimized cleanroom layouts to maximize semiconductor manufacturing efficiency.

Our Semiconductor Fab Facility Solutions cover end-to-end fab facility engineering services and semiconductor facility infrastructure services, ensuring efficient setup, integration, and maintenance of critical utilities. We specialize in process utility integration for semiconductor fabs, including UPW systems, and provide robust fab facility operations support to optimize performance and reliability. Whether for greenfield or brownfield fab facility support, we deliver precision, compliance, and efficiency across all semiconductor facility systems.

We ensure seamless integration of process-critical utilities, reliable facility operations, and compliance with stringent semiconductor manufacturing standards.

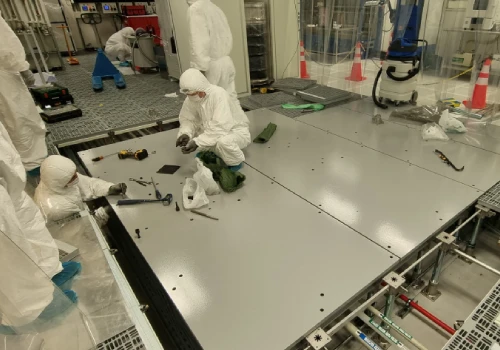

We design optimized cleanroom layouts to maximize semiconductor manufacturing efficiency.

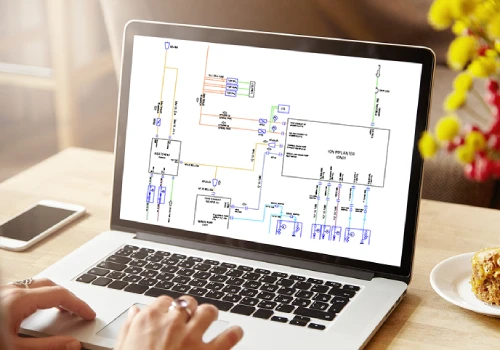

We prepare As-Fabricated and P&ID diagrams essential for cleanroom construction and utilities layout.

We execute cleanroom upgrades and modifications to support evolving semiconductor processes.

We install key cleanroom systems including fan filter units, air handlers, HVAC systems, flooring, and pedestals.

A disciplined, standards-driven methodology combining engineering expertise and operational excellence for advanced semiconductor fabrication facilities.

Performed in accordance with ISO 14644 standards to ensure contamination control and operational integrity of the entire facility.

Final system verification, comprehensive documentation handover, operational demonstration and full readiness confirmation for safe production use.

We offer comprehensive semiconductor facility and utility engineering solutions.

Contact Us

We offer end-to-end solutions including fab build services, facility maintenance, utility hook-up, precision tool deployment, and cleanroom validation.

Our process covers design, facility preparation, tool installation, hookup, qualification documentation, cleanroom validation, and handover to the end user.

We use in-house testing equipment up to 400 Bar, leak testers detecting down to 10-9 mbar.L/sec, orbital welding machines (up to 4" tubes), and non-metallic welding machines.

We deploy advanced precision tools and validation equipment to meet strict industry standards and ensure accurate, reliable results.

Our comprehensive in-house capabilities, specialized tools, and end-to-end support differentiate us as a trusted partner for semiconductor fabs.