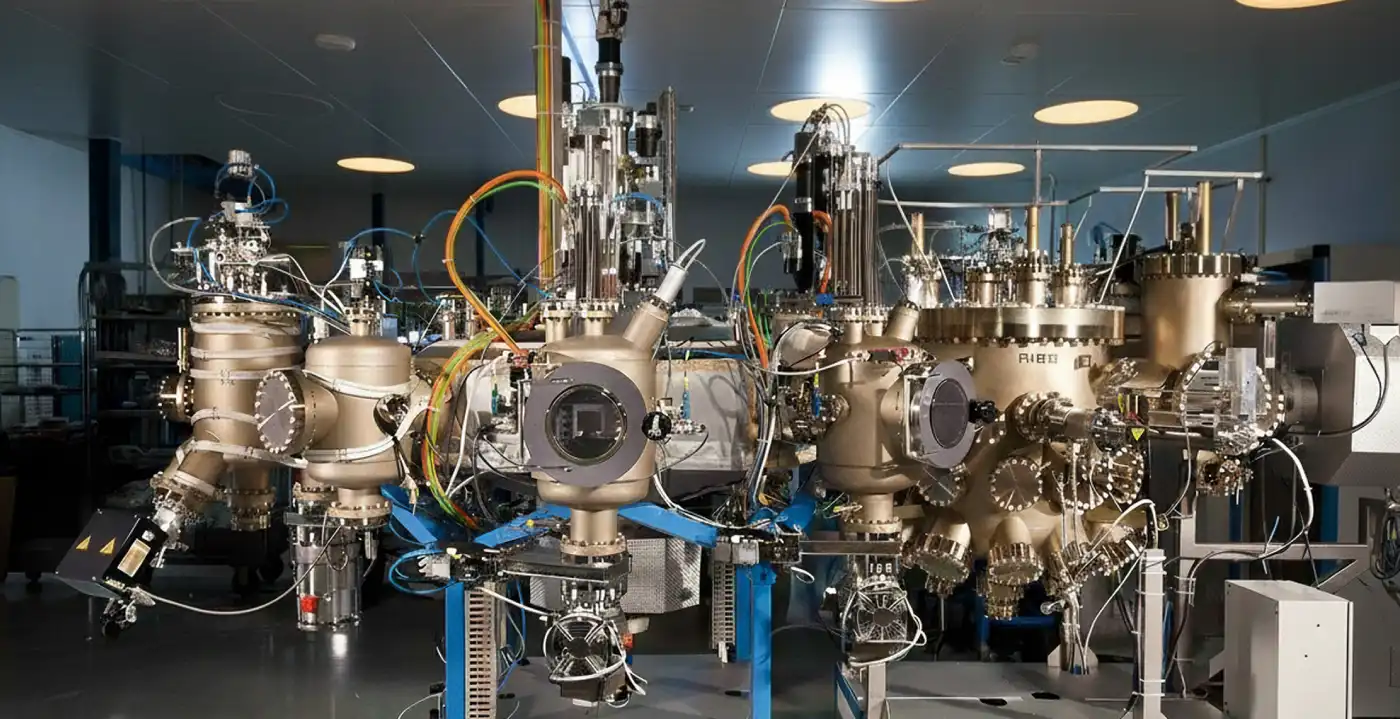

At Orbit & Skyline, we ensure your semiconductor FAB equipment achieves maximum uptime, reliability, and peak operational performance. Through our advanced semiconductor equipment engineering capabilities, we support fabs with proven expertise across installation, maintenance, and performance optimization. From uncrating to tool start-up, our Annual Maintenance Contracts (AMC) are tailored specifically for semiconductor FABs, backed by international engineering expertise, multi-module knowledge, and strong infrastructure support delivered by experienced semiconductor equipment engineers and field service teams.

We specialize in both CMOS and compound semiconductor FABs, offering end-to-end support including tool roll-ins, hardware qualifications, and process flow development. Our global network and hands-on workforce development initiatives ensure strong, consistent, and reliable equipment performance.