When you wake up and check your phone, drive to work, or pay for your coffee, you probably don’t think about the semiconductor chips working quietly in the background. Still, these integrated circuits are just as essential to modern life as electricity or clean water.

According to the Semiconductor Industry Association, global semiconductor sales in Q2 2025 reached USD 179.7 billion, marking a 7.8% increase quarter-on-quarter (semiconductors.org), and the World Semiconductor Trade Statistics (WSTS) organization projects the global semiconductor market will reach approximately USD 728 billion in 2025, reflecting an annual growth of 15.4% (source).

With the growing demand for AI, high-performance computing, electric vehicles, and IoT, fabs and OEMs face increasing pressure to deliver at scale with precision and reliability. Orbit & Skyline helps meet these challenges by working closely with fabs and OEMs to offer complete FAB Solutions and OEM Solutions that support efficient, reliable, and high-quality semiconductor production.

This blog examines the role of semiconductors in daily life and highlights the advanced technology and services behind each chip.

Let’s start with a basic question.

What are Semiconductors?

Semiconductors are materials that allow precise control of electrical current, forming the backbone of modern electronics. They enable the tiny circuits inside devices, from smartphones and medical equipment to electric vehicles and smart homes, turning raw silicon into the intelligent systems that quietly power our daily lives.

4 Places You See Semiconductors in Daily Life

![]()

Here’s how semiconductors are omnipresent, even where you might not notice them:

1. Consumer Electronics & Mobile Devices

Nearly every smartphone or tablet today uses a System-on-Chip, or SoC. This is a single chip that contains CPU cores, GPU or AI accelerators, memory controllers, and I/O blocks. Modern SoCs can have tens of billions of transistors, built on 3 nm or 5 nm technology.

2. Smart Homes & Internet of Things (IoT)

Devices like sensors, actuators, smart thermostats, home automation hubs, and voice assistants depend on compact, energy-efficient chips. These chips often use specialized mixed-signal and low-power technologies such as subthreshold logic and power gating.

3. Wearables & Health Trackers

These devices require strict power budgets and wireless connectivity, such as BLE or Wi-Fi. Some also include biometric or chemical sensors. To maintain battery life and accuracy, manufacturers use low-leakage processes and embedded memory or NPU accelerators.

4. Consumer Appliances & Embedded Systems

Modern appliances like washing machines, refrigerators, and HVAC systems come with “smart” functions, and each includes microcontrollers or embedded controllers to handle sensing, actuation, and connectivity.

If semiconductors “went offline” one day, the impact would be immediate: no internet traffic, limited energy control, disabled devices, and key infrastructure would fail.

How Semiconductors Drive Transportation

![]()

Modern vehicles function as complex networks of integrated chips.

1. Infotainment & Connectivity

Central computers managing user interface, voice control, map navigation, OTA updates.

2. Advanced Driver Assistance Systems (ADAS)

Radar, lidar, vision processing, sensor fusion, and real-time decision systems all rely on high-speed, deterministic compute.

3. Power Electronics & EV Systems

Battery management, inverter control, and motor drive algorithms demand efficient, robust analog/digital integration.

4. Autonomous Driving (in development)

Even more compute, sensor arrays, redundancy, fail-safe systems.

Automotive chips are required to comply with reliability standards, including Automotive Electronics Council (AEC) Q100 and Q200. These components must also undergo temperature cycling, vibration testing, lifetime stress evaluation, and implementation of fault detection mechanisms.

When OEMs and fabs develop chips for automotive or mobility use cases, they often require specialized test setups, custom tooling, and system integration. Orbit & Skyline’s OEM Solutions can assist with integration, validation, and testing of the chip in vehicle subsystems.

How Semiconductors Are Transforming Healthcare

![]()

Semiconductors have become foundational to modern medicine. Some examples are listed below:

1. Medical Imaging

CT, MRI, PET scanners all use high-performance analog & digital chips for signal acquisition, processing, and control.

2. Implantable Devices

Pacemakers, neural stimulators, insulin pumps, all need ultra-reliable, low-power ICs with often decades of lifetime.

3. Diagnostics & Lab Devices

DNA sequencing, point-of-care sensors, lab automation depend on chips for signal conditioning, amplification, and data processing.

4. Wearable Health Monitors

Continuous glucose monitors, ECG patches, SpO2 sensors, etc.

Chips used in medical devices usually need to meet standards like ISO 13485 and FDA 510(k). They also have to be compatible with gamma sterilization and maintain very low soft error rates. Manufacturing should ensure traceability, process control, and high yields.

Orbit & Skyline’s Process Engineering and Equipment Engineering support fabs to meet the stringent yield, reliability, and compliance demands required by medical-grade semiconductor production.

How Semiconductors Enable Data, Connectivity, and Security

This is where much of the “invisible” impact of semiconductors is felt, powering the critical systems behind our cloud services, high-speed networks, data security, and financial infrastructure, even though we rarely see the chips at work.

1. Data Centers & Cloud Computing

High-performance computing, AI accelerators, and large-scale storage depend on logic, memory, interconnect, and high-bandwidth memory (HBM). According to PwC’s “Semiconductor and beyond” report, the semiconductor market is projected to grow from USD 627 billion in 2024 to ~USD 1 trillion by 2030 (CAGR ~8.6 %), driven heavily by server and network segments.

2. Networking & Telecom Infrastructure (5G/6G)

Base stations, routers, switches all rely on high-throughput, low-latency semiconductor solutions.

3. Security & Finance

Hardware security modules, secure enclaves, encryption accelerators, trusted platform modules (TPMs), and secure ICs play a vital role in banking, blockchain, and data integrity systems.

In 2025, global semiconductor manufacturing equipment (OEM) sales are expected to reach USD 125.5 billion, with wafer fab equipment (WFE) accounting for USD 110.8 billion of that. This underscores the intense capital flows into enabling infrastructure. (Source)

The chips powering these systems are manufactured using highly specialized semiconductor equipment, where Orbit & Skyline’s OEM Services provide end-to-end support including system integration, installation, calibration, testing, and field services, helping OEMs ensure tools operate reliably and meet performance requirements across fabs worldwide.

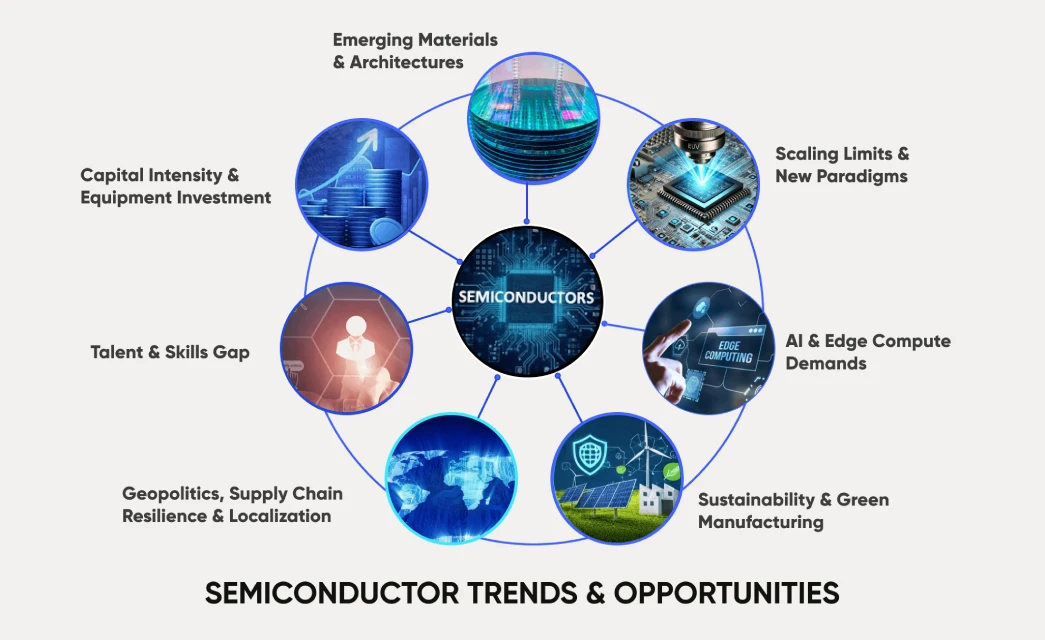

The Road Ahead: Semiconductor Trends, Challenges & Opportunities

The semiconductor industry is changing rapidly, driven by new technology, sustainability efforts, and changes in global manufacturing. Here’s a technical view of what lies ahead:

1. Emerging Materials & Architectures

Compound semiconductors such as SiC and GaN are changing power electronics and RF uses. At the same time, chiplet designs and 3D stacking are improving how chips are built and how well they perform.

2. AI, Edge, and Compute Demands

As AI and edge computing grow, there is more need for specialized accelerators and high-bandwidth memory. This is raising the bar for how much computing power and energy efficiency chips can deliver.

3. Sustainability & Localization

Fabs are moving toward green manufacturing, focusing on water recycling, renewable energy, and waste reduction, while nations invest in localized fabs to strengthen supply chain resilience and reduce geopolitical dependency.

4. The Talent Imperative

As the chip industry grows worldwide, there is a bigger gap in skills. There are not enough experts in process, materials, and equipment engineering, so more training and teamwork are needed.

Orbit & Skyline’s Role

As fabs scale for next-generation technologies, we support this transformation through our expertise in FAB Solutions and OEM Services, helping clients optimize tool performance, process integration, and material quality. Beyond equipment and processes, we are shaping the next generation of semiconductor talent through hands-on training, simulation-based learning, and mentorship, preparing engineers to operate confidently in real fab environments and ensuring a skilled workforce ready to drive innovation across the semiconductor industry.

Conclusion

Semiconductors power nearly every aspect of our modern lives, from smartphones and smart homes to AI-driven data centers and secure financial systems. Each chip relies on a detailed process of design, manufacturing, and integration. At Orbit & Skyline, we help keep this process running smoothly. With our FAB Solutions, OEM Services, and practical training programs, we support fabs and OEMs worldwide so they can work efficiently and dependably. We train engineers to meet the changing needs of the semiconductor industry. By combining technology and skilled people, we help drive the innovations that connect our world.

With 15+ years of expertise and a global team of 500+ engineers, Orbit & Skyline is a trusted partner in the semiconductor industry. If you are looking for a semiconductor services and solution partner, reach out to us at hello@orbitskyline.com.

Semiconductor FAB Solutions

Semiconductor FAB Solutions

OEM Solutions

OEM Solutions